Top 5 Warning Signs Your Gearbox Is About to Fail

Avoid Costly Downtime by Spotting These Red Flags Early

When it comes to industrial machinery, your gearbox is the heart of your power transmission system. But like any critical component, it can wear down or fail—often at the worst possible time. Fortunately, gearboxes rarely give out without warning. At Troy Industrial Solutions, we’ve helped manufacturers across the Northeast spot and solve gearbox issues before they result in costly shutdowns.

Here are the top five warning signs your gearbox might be headed for trouble:

1. Unusual Noises or Vibration

If your gearbox starts making grinding, whining, or knocking noises, it could signal worn or misaligned gears, damaged bearings, or insufficient lubrication. Vibration is often an early symptom of internal wear and misalignment that can quickly escalate if ignored.

Troy Tip: Field service technicians can use advanced vibration analysis tools to catch these problems before they lead to catastrophic failure.

2. Excessive Heat

Gearboxes naturally generate heat, but excessive temperatures can indicate overloading, poor lubrication, or internal friction. Overheating can degrade gear oil, warp internal components, and shorten equipment life.

Did You Know? Troy offers thermal imaging inspections and gearbox cooling system upgrades to help maintain optimal operating conditions.

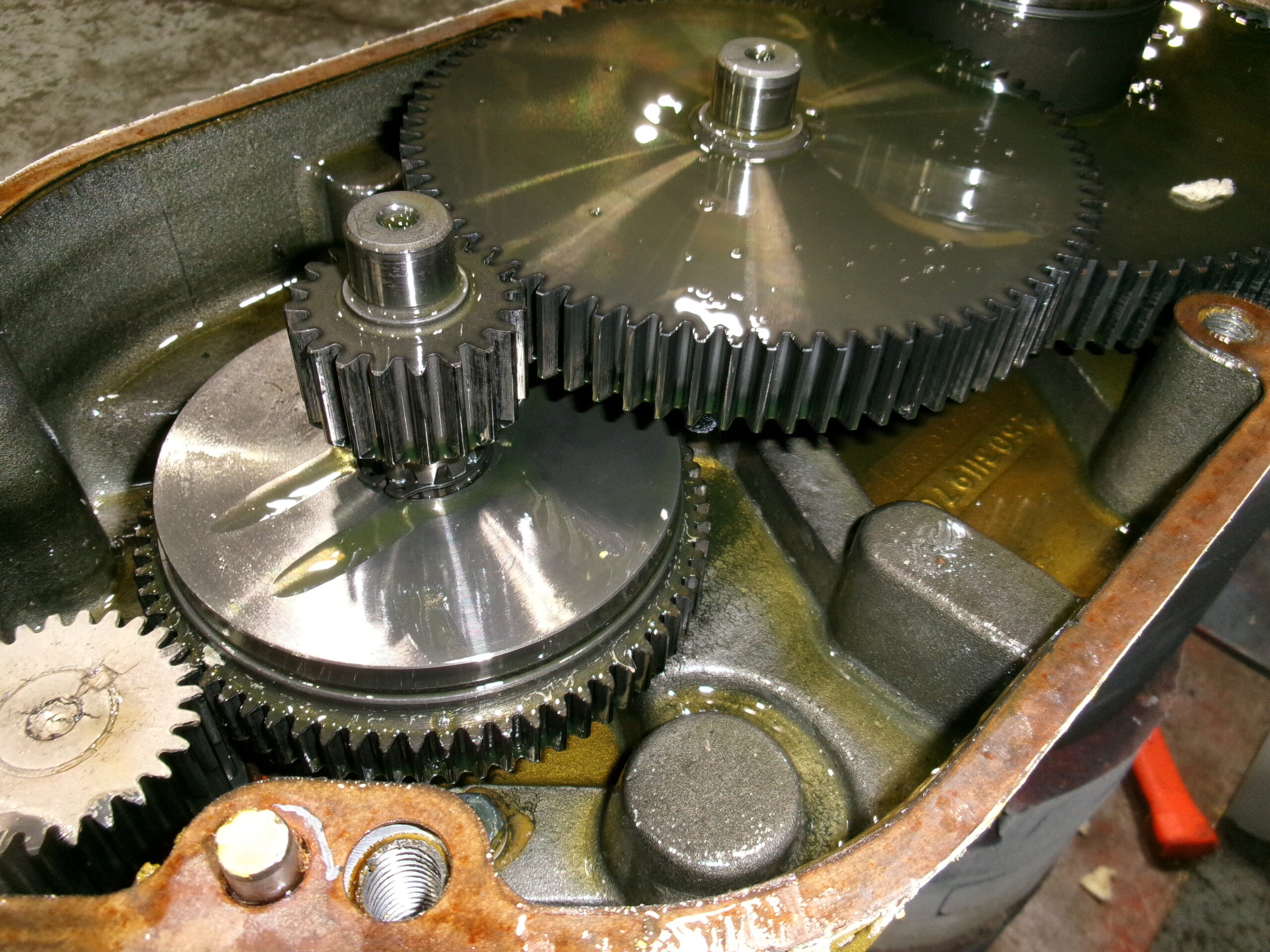

KODAK Digital Still Camera

3. Oil Leaks or Contamination

If you notice oil pooling under your gearbox or see cloudy, milky, or gritty oil during inspection, it’s time to act. Contaminants like water, dirt, or metal shavings can destroy internal components and cause premature failure.

Troy Solution: Our team provides oil sampling and filtration services, plus high-efficiency breather and seal retrofits that help keep your gearbox clean and leak-free.

4. Poor Performance or Inconsistent Output

Is your equipment lagging, slowing down, or behaving erratically? A failing gearbox may struggle to deliver consistent power due to slipping gears, internal wear, or torque issues.

Fix It Fast: Troy’s gearbox rebuilds and retrofits restore performance, often at a fraction of the cost of full replacement.

5. Visible Wear or Damage

Cracked housings, loose mounting bolts, or worn shafts are obvious signs of trouble. Ignoring these visible red flags can lead to complete gearbox failure, unplanned downtime, and significant repair costs.

Inspect Regularly: Troy offers routine inspections and preventative maintenance programs tailored to your facility’s needs and schedule.

Don’t Wait for Failure—Plan Ahead!

Gearbox failures can bring production to a standstill, but with the right knowledge and support, they’re preventable. At Troy Industrial Solutions, we specialize in gearbox inspection, maintenance, repair, and replacement, offering on-site diagnostics and complete rebuilds in our dedicated repair facilities.

Need a Gearbox Health Check?

Let Troy Industrial Solutions keep your operations running smoothly. Contact us today to schedule a consultation or request emergency service.

Your gearbox won’t fix itself—trust the experts at Troy to keep it in motion.