Understanding Screw Conveyors

Q: What is a screw conveyor?

A: A screw conveyor is a straightforward machine that efficiently moves bulk materials. Imagine a large screw rotating inside a tube, gently pushing materials forward. That’s essentially how a screw conveyor works.

Q: What are the critical components of a screw conveyor?

A: The main parts include a rotating screw (auger) enclosed within a trough. The screw’s flights (blades) move material along the trough. An electric motor and gearbox provide power for rotation. Inlet and outlet openings allow for material entry and exit.

Q: What industries benefit from screw conveyors?

A: Screw conveyors are incredibly versatile and benefit various industries, including:

-

Forest Products: Sawmills, plywood mills, and furniture manufacturers use screw conveyors for removing sawdust, chips, and bark.

-

Biomass Power: These plants use screw conveyors to feed wood fuel and remove ash.

-

Pulp and Paper: Screw conveyors are used to mix chemicals and feed wood chips in the pulping process.

-

Wastewater Treatment: Screw conveyors help move treated sludge for disposal.

Q: Why are screw conveyors so popular?

A: Their popularity stems from their simplicity, reliability, and cost-effectiveness. They have few moving parts, are easily enclosed for dust control, and offer efficient material transfer without spillage.

The TIS Advantage

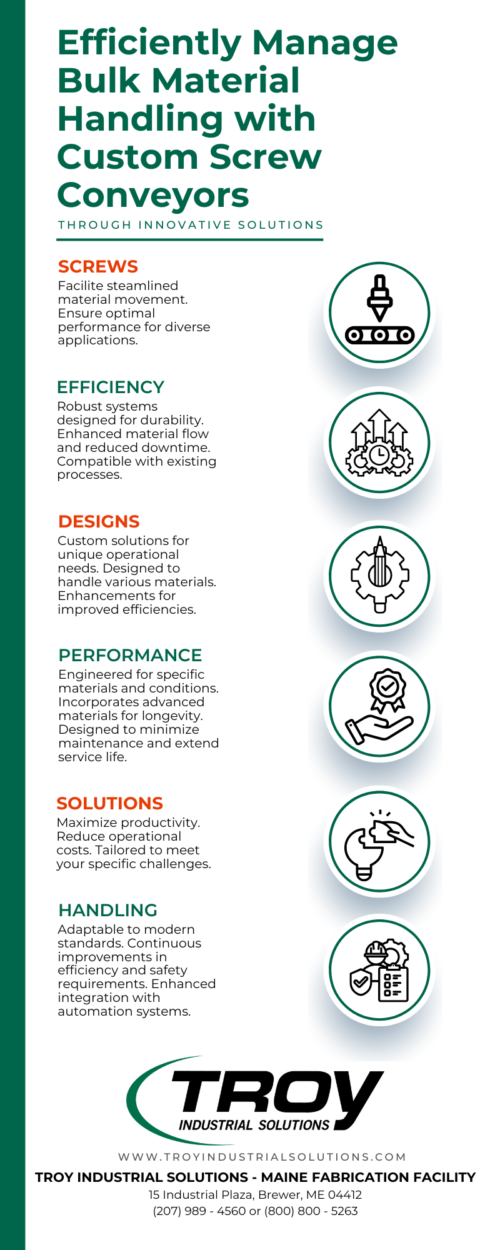

Q: What distinguishes TIS screw conveyors?

A: TIS stands out for its extensive experience and deep product knowledge. We offer two types of screw conveyors:

-

Standard CEMA (Conveyor Equipment Manufacturers Association) Conveyors: Industry-standard components readily available for fast turnaround.

-

Custom-Engineered Conveyors: Designed and built to order, utilizing our expertise in material handling, abrasion and corrosion-resistant materials, and customized power transmission drives.

Q: How does TIS’s location benefit Northeast and Mid-Atlantic clients?

A: Our location in Brewer, Maine, right off Interstate 95, helps with quicker turnaround times, lower shipping costs, and swift responsiveness to the needs of our regional clients in the Northeast and Mid-Atlantic.

Specifications and Customization

Q: What materials can TIS screw conveyors handle?

A: Our screw conveyors can handle a wide range of bulk materials classified by CEMA standards based on density, size, flowability, and abrasiveness. Contact us to discuss your specific material for optimal solution recommendations.

Q: What size screw conveyors does TIS offer?

A: We provide screw conveyors ranging from 3″ to 48″ in diameter, tailored to your required capacity and space constraints. For longer runs, multiple conveyors can be connected.

Q: Does TIS offer different screw designs?

A: Yes, we offer different screw designs, including:

-

Sectional Flights: The most common type is made by bending steel blanks.

-

Ribbon Flights: Ideal for sticky materials like sludge.

-

Shaftless Screws: Specialized for sticky materials or large, bulky objects.

Q: Does TIS prefer customization or standard sizing?

A: We offer both! Our CEMA standard components are often sufficient for general applications. However, we encourage customized materials and upgrades for enhanced durability and lifespan.

Maintenance and Support

Q: What safety considerations should I be aware of when operating a screw conveyor?

A: Operating a screw conveyor safely requires awareness of potential hazards. While TIS conveyors are designed and manufactured to meet OSHA regulations and feature clear safety markings, it is crucial to prioritize safety:

-

Lockout/Tagout: Always de-energize and lockout the conveyor before accessing any openings or performing maintenance.

-

Guarding: Ensure all guards are in place and secure during operation to prevent contact with moving parts.

-

Emergency Stop: Be familiar with the location and operation of emergency stop devices.

-

Training: Only trained personnel should operate or maintain the conveyor.

-

Company Procedures: Always adhere to your company’s safety procedures and guidelines.