For most modern manufacturing facilities, unplanned or unscheduled downtime is a costly disaster. The trained and experienced professionals at Troy Industrial Solutions will help you survey your maintenance requirements, assess the maintenance status of critical components, and put in place a maintenance program customized-designed to match your production demands.

We offer a range of predictive and preventative field service services including:

- Laser Alignment

- Balancing

- Thermography

- Non-Destructive Motor Testing (PDMA)

- Bearing Inspection

- Bearing Fluting Mitigation

Thermography Services

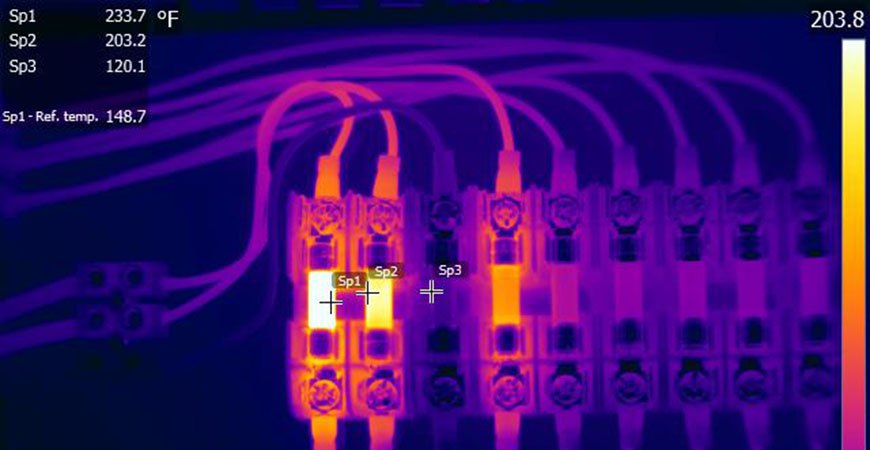

At Troy Industrial Solutions, we use advanced electrical thermography to help customers identify potential equipment problems before they cause costly downtime or failures. Our thermography testing utilizes a thermal imaging camera to detect heat rather than visible light, allowing our technicians to see temperature differences across electrical systems — including panels, breakers, fuses, and wiring.

These detailed images reveal hot spots that often signal hidden issues such as loose connections, unbalanced loads, deteriorating insulation, or overloaded circuits — problems that can’t be seen with the naked eye but can lead to serious safety or performance concerns if left unaddressed.

Our inspections are performed using the FLIR T865 thermal camera, a state-of-the-art tool equipped with multiple lens options to safely capture heat signatures from a distance. This technology delivers sharp, high-resolution images and can measure temperature ranges from -40°F to 3600°F, detecting even the smallest variations. The result is a non-contact, efficient, and accurate inspection method that keeps your facility safe and your operations running smoothly.

We provide thermography services across a wide range of industries — including manufacturing, utilities, food processing, water treatment, automotive, and commercial facilities — anywhere electrical reliability is essential.

With Troy Industrial Solutions’ thermography services, you get early detection, improved safety, and peace of mind, ensuring your electrical systems perform at their best.

Predictive/Preventative Field Service FAQs