Having the proper seal configuration is one of the keys to minimizing hydraulic leaks in production equipment

The Problem:

The Problem:

A national block manufacturer was having a chronic problem with leaky trunion cylinders in their production facility. During operation the packing gland would vibrate loose and hydraulic fluid would seep past the seals and drip onto the finished product. Every few weeks a maintenance technician crawled into very tight quarters to retighten the gland with a hammer and punch. Often during the retightening process the technicians nicked the rod, created a leak and ultimately shortened the life of the cylinder.. The cylinder averaged 2-3 months before it was removed and repacked on-site by the maintenance technicians.

The Analysis:

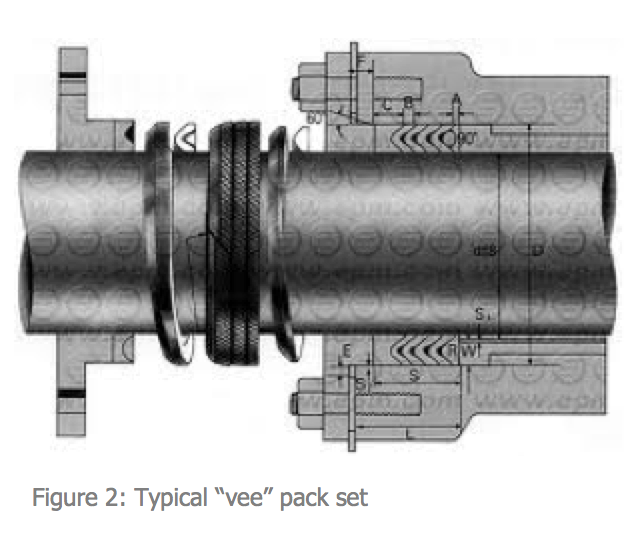

After closely evaluating the cylinder design, we determined the traditional stacked “vee” style seals were not handling the vibration caused by the inverted mounting position of the trunion cylinder.The rod was extending down from the trunion creating a tremendous amount of stress in the application.

The Solution:

The Solution:

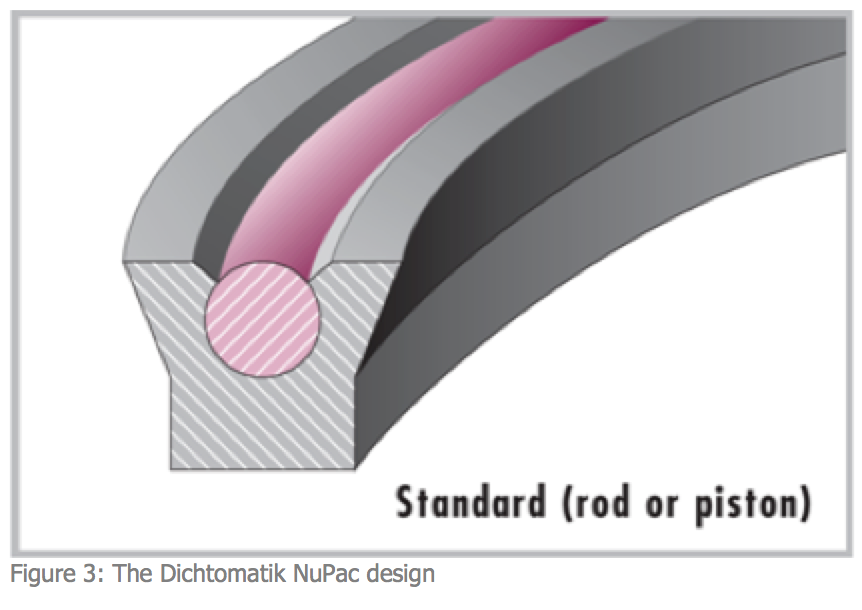

We retrofitted the cylinder with a Dichtomatik NuPac – Loaded U-Cup seal design. The NuPac is a combination seal consisting of a U-Cup and O-Ring. As the system pressure increases the O-Ring forces the lips of the U-Cup outward and maintains contact with the cylinder tube. We also modified the packing gland with a set screw to prevent it from vibrating loose.

The redesigned solution with the NuPac seal is still in service after 10 months of operation with no leaks. The customer was so pleased with the results they are now sending all of their cylinders in for repair to Troy. They are also planning to bring cylinders from other locations to have the seals retrofitted at our hydraulic repair shop.

The NuPac from Dichtomatik has several advantages over the traditional “vee” seal packing designs;

- 6000 PSI maximum operating pressure

- Works well in low pressure applications

- Several materials; polyurethane, FKM, XNBR, HNBR and more

- Interchangeable with other types of seal configurations

- Works well as a piston or rod seal

So next time you have a leaky cylinder don’t waste money by putting a band aid on it …. fix it for good.

For more information on Hydraulic Repair Services, contact us 518.272.4920.