At Troy Industrial Solutions, we are dedicated to ensuring industries run smoothly. With extensive experience in conveyor belts, we’ve seen these systems evolve from simple setups to complex networks spanning entire factories. One constant truth is that a clean conveyor belt is crucial for a safe, efficient, and profitable operation.

The Carryback Conundrum: A Small Problem with Big Consequences

Let’s talk carryback – that material that stubbornly sticks to your belt after unloading. It might appear harmless initially, like a bit of dust or a few stray particles clinging to the underside. But don’t be fooled! Just like a tiny leak that can quickly escalate into a costly flood, carryback can wreak havoc on your entire production line if left unchecked.

Here’s a breakdown of the problems that can arise when carryback is neglected:

- Misalignment: Carryback acts like a relentless builder, gradually accumulating on rollers and pulleys. This buildup eventually forces your belt off its intended path, leading to uneven wear and tear, premature belt failure, and the expensive hassle of replacing a critical component.

- Spillage: As your belt starts to wobble and wander due to the growing carryback burden, valuable material spills onto the floor. This means lost product, wasted resources, cleanup headaches, and a potential safety hazard for your workers.

- Increased Wear and Tear: Think of carryback as sandpaper on your belt and components. The constant friction and abrasion accelerate wear and tear, leading to more frequent maintenance, unexpected downtime, and costly repairs that could have been easily prevented.

- Safety Risks: Spilled material, a misaligned belt, and employees rushing to clean up the mess create a dangerous environment where accidents and injuries are more likely to occur. Your workforce is your most valuable asset; their safety should never be compromised.

Belt Cleaning: A Holistic Approach, Not a Quick Fix

At Troy, we understand that tackling carryback isn’t a one-and-done deal. It requires a comprehensive, tailored approach that addresses the unique challenges of your specific conveyor system. That’s why we offer a diverse range of belt cleaners to fit every need:

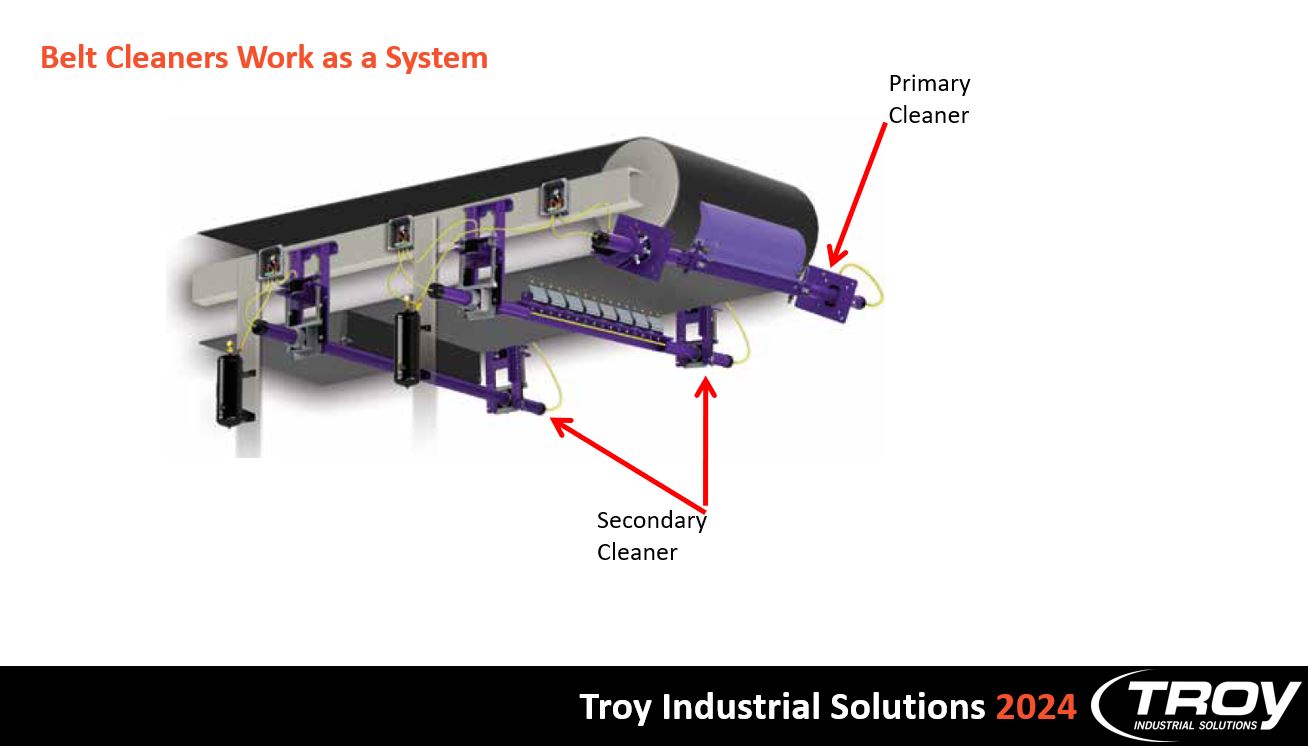

- Primary Scrapers: These heavy-duty scrapers are the first line of defense, removing the bulk of material right at the head pulley before it has a chance to cause trouble.

- Secondary Cleaners: Strategically positioned further along the belt path, secondary cleaners target finer residues and particles that primary cleaners might miss, ensuring a thorough cleaning process.

- Specialized Cleaners: We offer specialized cleaners for every situation – U-type cleaners for heavy-duty applications, chevron and motorized brush cleaners for textured belts, and even diagonal plows for the return side.

- Hold Down Roll for Secondary Cleaners: This component ensures maximum efficiency by maintaining consistent contact between the secondary cleaner and the belt, guaranteeing a thorough cleaning action.

Expert Guidance, Tailored Solutions

Expert Guidance, Tailored Solutions

Our commitment to you goes beyond simply providing equipment. We’re your partners in finding the most effective belt-cleaning strategy for your unique needs. Our team of experienced engineers will visit your facility, conduct a comprehensive analysis of your conveyor system, and recommend the ideal combination of cleaners based on factors like the type of material you’re conveying, belt speed, operating environment, and budget. Conveyor Belt Cleaning.

Invest in Cleaning, Reap the Long-Term Rewards

Investing in a quality belt cleaning system isn’t just about fixing a current problem; it’s about preventing future problems and optimizing your entire operation. When you prioritize a clean belt, you’ll enjoy a multitude of benefits:

- Maximize Uptime: A clean, well-maintained belt operates smoothly and reliably, minimizing unexpected breakdowns and ensuring maximum production time.

- Extend Equipment Life: By reducing wear and tear, you’ll extend the lifespan of your conveyor belt and components, delaying the need for costly replacements.

- Boost Profits: Fewer breakdowns, less material waste, and increased efficiency translate directly to a healthier bottom line.

- Enhance Safety: A clean and organized workplace is safer, minimizing the risk of accidents and injuries to your employees.

Don’t Wait for Carryback to Become a Crisis

Don’t let carryback continue to hinder your productivity, compromise your profits, and jeopardize the safety of your workers. Contact Troy Industrial Solutions today. We’ll help you develop a comprehensive belt-cleaning strategy that keeps your operation running smoothly, your employees safe, and your profits rising.

With over 162 years of experience, we’re experts at keeping industries running. Let us use our expertise to help you achieve the full potential of your conveyor system. For more information, visit our FAQ page on conveyor belt maintenance.