Year-End Maintenance Checklist: Prepare Your Facility for Success in 2026

As the year draws to a close, now is the perfect time to assess your facility’s equipment and maintenance needs. A comprehensive year-end maintenance plan ensures you start the new year with optimized performance, minimal downtime, and a proactive approach to equipment reliability. At Troy Industrial Solutions, we’ve been helping industrial facilities across the Northeast maintain peak performance since 1862, and we understand that proper year-end maintenance is crucial for long-term success.

Why Year-End Maintenance Matters

Why Year-End Maintenance Matters

Year-end maintenance isn’t just about checking boxes—it’s about protecting your investment and ensuring operational continuity. The benefits of a thorough year-end maintenance program include:

Preventing Costly Downtime: Unplanned equipment failures can cost thousands of dollars per hour in lost production. By identifying and addressing potential issues before they become critical failures, you protect your bottom line and maintain production schedules.

Extending Equipment Lifespan: Regular maintenance significantly extends the life of your motors, conveyors, drives, and other critical equipment. This means you’ll maximize your return on investment and delay expensive capital expenditures.

Improving Safety: Well-maintained equipment is safer equipment. Year-end inspections help identify potential safety hazards before they put your team at risk, creating a safer work environment for everyone.

Optimizing Energy Efficiency: Equipment that’s properly maintained runs more efficiently, consuming less energy and reducing your utility costs. Small efficiency gains across multiple systems can add up to substantial savings.

Planning Your Budget: A comprehensive year-end assessment gives you visibility into upcoming maintenance needs, allowing you to budget accurately for the coming year and avoid financial surprises.

Key Areas to Inspect: Conveyors, Motors, and Drives

Your facility’s critical equipment requires careful attention during year-end maintenance. Here are the key areas to focus on:

Electric Motors

Motors are the workhorses of industrial facilities, and their health directly impacts your operations. During your year-end inspection, examine motors for signs of wear, unusual noises, vibration, or overheating. Check for proper lubrication, inspect bearings for wear, and verify that cooling systems are functioning properly. Review motor performance data to identify any efficiency losses.

Pay special attention to motor windings, as degradation can lead to complete failure, requiring rewind service. If you notice any concerning signs, consider scheduling a professional motor inspection. Troy Industrial Solutions’ experienced technicians can perform comprehensive motor diagnostics at our service center in Watervliet, NY, or our facility in Ansonia, CT.

Conveyor Systems

Conveyor systems require thorough inspection to ensure reliable material handling. Start by examining belting for cuts, tears, fraying, or excessive wear. Check belt tracking to ensure proper alignment, as misalignment causes premature wear and can lead to system failure. Inspect rollers and idlers for smooth rotation and replace any that show signs of bearing failure or damage.

Examine drive pulleys and tensioning systems to ensure they’re functioning correctly. Look for buildup of material that could cause tracking issues or put unnecessary stress on the system. Check all fasteners, guards, and safety systems to ensure they’re secure and functioning properly. For conveyor systems showing signs of significant wear, consider scheduling repairs or upgrades before the new year begins.

Variable Frequency Drives (VFDs) and Controls

Variable Frequency Drive systems and controls are critical for efficient motor operation. Inspect VFD cabinets for dust accumulation, which can cause overheating and failure. Clean cooling fans and verify that ventilation is adequate. Check all electrical connections for tightness and signs of overheating or corrosion.

Review VFD programming and parameters to ensure they’re optimized for your current operations. Check for error logs or fault histories that might indicate underlying problems. Verify that safety interlocks and emergency stops are functioning correctly. If your drives are outdated or showing signs of unreliability, year-end is an excellent time to plan for upgrades.

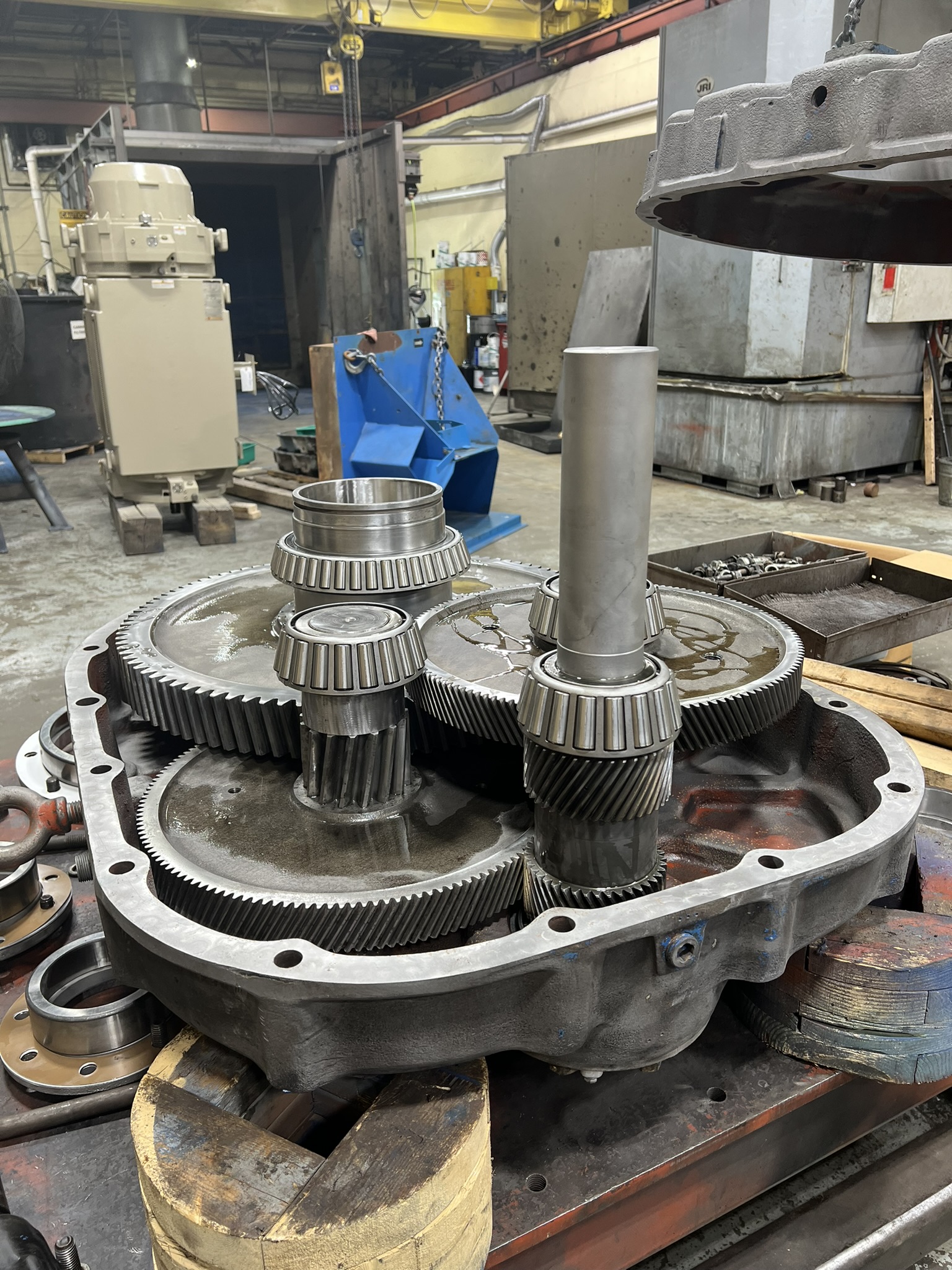

Gearboxes and Reducers

Inspect gearboxes for oil leaks, unusual noise, or excessive vibration. Check oil levels and condition—if the oil appears dark, contaminated, or smells burnt, schedule an oil change. Examine seals for deterioration and breather vents for blockages. Review maintenance logs to ensure oil changes are being performed on schedule, and plan for any overdue maintenance.

Pumps and Fans

Check pumps for leaks, unusual vibration, or cavitation noises. Inspect seals, bearings, and alignment. For fans and blowers, examine belts for wear and proper tension, inspect bearings, and verify that airflow is adequate for your application. Clean accumulated debris that could impact performance or cause overheating.

Scheduling Repairs and Preventive Maintenance

Once you’ve completed your inspections, it’s time to prioritize and schedule necessary work. Here’s how to approach this strategically:

Categorize Issues by Priority

Divide identified issues into three categories: critical repairs needed immediately to prevent failure or safety hazards, important repairs that should be completed within the next quarter, and routine maintenance that can be scheduled during planned downtime. This approach ensures that the most urgent issues receive immediate attention while nothing gets overlooked.

Take Advantage of Holiday Shutdowns

Many facilities have scheduled shutdowns during the holiday season or early January. This is the ideal time to tackle major repairs or overhauls that would otherwise require production stops. Plan these projects well in advance to ensure parts availability and technician scheduling.

Schedule Preventive Maintenance

Work with your maintenance provider to establish a preventive maintenance schedule for the coming year. Regular preventive maintenance is far less expensive than emergency repairs and significantly reduces the risk of unexpected failures. Troy Industrial Solutions offers comprehensive preventive maintenance programs tailored to your facility’s specific needs, with 24/7 availability to support your operations.

Plan for Long-Lead Items

Some repairs require parts with long lead times or complex coordination. Identify these needs early so you can order parts and schedule work without production impacts. Having critical spare parts in inventory can dramatically reduce downtime when equipment fails.

Tips for Optimizing Equipment Performance

Beyond repairs and maintenance, consider these strategies for optimizing your equipment’s performance:

Implement Predictive Maintenance Technologies: Modern predictive maintenance tools like vibration analysis, infrared thermography, and oil analysis can identify problems before they cause failures. These technologies provide early warning of developing issues, allowing you to schedule repairs proactively. Troy Industrial Solutions offers comprehensive predictive and preventative field service that can help you transition from reactive to proactive maintenance.

Upgrade to Modern Controls: If your facility is still running older control systems, upgrading to modern VFDs and controls can improve efficiency, reduce energy consumption, and provide better diagnostic capabilities. Newer systems often pay for themselves through energy savings and improved reliability.

Optimize Operating Parameters: Review how your equipment is being operated and look for optimization opportunities. Motors running at incorrect speeds, conveyors carrying unnecessary loads, or systems running during idle times all represent opportunities for efficiency improvements.

Improve Documentation: Create or update equipment documentation, including model numbers, serial numbers, maintenance histories, and operating parameters. Good documentation makes troubleshooting faster and helps ensure maintenance is performed correctly and on schedule.

Invest in Training: Ensure your maintenance team has the skills and knowledge they need to keep equipment running optimally. Troy Industrial Solutions offers training programs that can help your team develop expertise in equipment maintenance and troubleshooting.

Consider Strategic Upgrades: Sometimes the best maintenance decision is to replace aging equipment that’s becoming unreliable or inefficient. Use your year-end assessment to identify equipment that’s reaching the end of its useful life and plan for replacements that will improve reliability and performance.

Planning for the Year Ahead

Year-end maintenance isn’t just about addressing current issues—it’s also about strategic planning for the coming year. Consider these elements as you develop your 2026 maintenance strategy:

Create a Maintenance Calendar: Develop a comprehensive maintenance calendar for the year that includes all scheduled preventive maintenance, anticipated repairs based on equipment age and condition, and planned downtime windows. Share this calendar with operations and production teams to ensure everyone understands when maintenance activities will occur.

Establish Parts Inventory: Identify critical spare parts that could prevent extended downtime and ensure they’re in stock. Work with your supplier to establish inventory levels for commonly needed items. Troy Industrial Solutions maintains millions of dollars in stocked inventory and belting material, ensuring fast access to the parts you need.

Budget Appropriately: Use insights from your year-end assessment to develop an accurate maintenance budget for 2026. Include not just routine maintenance but also anticipated repairs and strategic upgrades. A realistic budget prevents surprises and ensures you have resources available when needs arise.

Build Supplier Relationships: Establish strong relationships with reliable maintenance and repair partners who can support your operations. Having established relationships means faster response times and better service when urgent needs arise. Troy Industrial Solutions has been a trusted partner to industrial facilities across the Northeast for over 163 years, providing comprehensive service, repair, supplies, fabrication, and maintenance support.

Set Performance Metrics: Establish key performance indicators for equipment reliability, maintenance costs, and downtime. Track these metrics throughout the year to identify trends and opportunities for improvement.

Review and Learn: Take time to review what worked well and what didn’t in 2025. Use these lessons to improve your maintenance approach in the coming year. Continuous improvement is key to world-class maintenance performance.

Conclusion: Start the New Year with a Smooth-Running Facility

A comprehensive year-end maintenance program is one of the best investments you can make in your facility’s future. By systematically inspecting equipment, addressing identified issues, and planning strategically for the year ahead, you set the stage for a productive, profitable 2026 with minimal unexpected downtime and optimal equipment performance.

Remember, you don’t have to manage all of this alone. Troy Industrial Solutions offers the most complete range of industrial service, repair, supplies, fabrication, and maintenance support in the Northeast. With four facilities, a mobile service fleet, experienced technicians, and 24/7 availability, we have the people and parts to keep your facility running smoothly throughout the year.

Whether you need motor repair and rewind services, conveyor maintenance and fabrication, field service support, pump and gearbox repair, machining services, or comprehensive preventive maintenance programs, Troy Industrial Solutions has the expertise and resources to help. We’ve been keeping industry running since 1862, and we’re here to support your success in 2026 and beyond.

Contact Troy Industrial Solutions today to schedule your year-end maintenance assessment and develop a comprehensive plan for the coming year. Let us help you start 2026 with confidence, knowing your equipment is in peak condition and your maintenance strategy is solid.

Visit us online at troyindustrialsolutions.com to learn more about our services and how we can support your facility’s maintenance needs.